Environmental protection at Deutsche Giessdraht GmbH

Deutsche Giessdraht GmbH produces high-quality copper wire rod. Founded in 1975, the company is based in Emmerich am Rhein, with excellent connections to shipping and the road and rail networks. Aurubis AG has held 100% of the shares in Deutsche Giessdraht GmbH since 2018.

Around 120 employees at DG produce up to 300,000 t of wire rod every year. The production process consists of melting, casting, rolling, pickling and winding the copper. The wire production facilities are state of the art and fulfill all product quality, environmental protection, and energy efficiency requirements.

The exhaust gas from the melting furnace is cleaned in a modern filter system, which ensures clear adherence to the limit values. The copper removal system integrated into production ensures that the wire cooling water is treated using state-of-the-art technology and that the monitoring values for copper in the cooling water fall well below the limit.

In recent years, we have invested in a number of projects to continuously modernize our plant. Today, an international comparison of wire rod plants has shown that Deutsche Giessdraht GmbH is very well positioned when it comes to energy efficiency. Introduced in 2012, the energy management system in accordance with ISO 50001 is a valuable aid in securing and further improving the level achieved. The site has also successfully implemented an environmental management system in accordance with ISO 14001 and, together with ISO 45001 and ISO 9001, successfully recertified it in 2025.

The site has also successfully implemented an environmental management system in accordance with ISO 14001 and an energy management system in accordance with ISO 50001, which was successfully recertified in 2024.

Environmental protection Deutsche Giessdraht – facts & figures

Water is mainly used for cooling. Cooling water withdrawal is constantly adjusted to meet current consumption. The intelligent pump control system with variable rotational speed has sustainably reduced specific water consumption in recent years, although this is also subject to natural fluctuations.

Thanks to the intelligent pump control system with variable speed, specific water consumption has been kept at a low level in recent years, although it is also subject to natural fluctuations.

Water utilisation in m³/t of wire rod produced

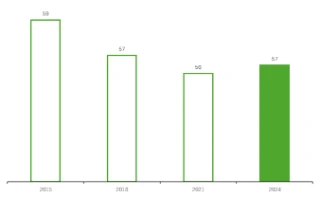

Electricity is mainly consumed by the rolling mill, as well as by drives for pumps, compressors, blowers, lighting, etc. Thanks to the extensive modernization of components and the strict use of energy-efficient drive systems, it has been possible to reduce specific electricity consumption from 75 to 57 kWh/t of wire rod output since 2005 (a nearly 25 % reduction).

Specific energy consumption kWh/t wire rod

Current environmental goals and projects

Implementation of the group-wide decarbonization roadmap

- Degree of implementation / next steps: In progress. Concepts submitted in October 2025, qualification for the next bidding phase of the climate protection agreements

Testing of hydrogen burners

- Status: In implementation

- Test run for new cooling water concept for improved water use

- New pumps

Status: In implementation

Milestones in environmental protection

- New discharge permit obtained, valid until 2039

- Wastewater treatment: Replacement of reverse osmosis resin bed in July 2025

- Replacement of all filter bags in the exhaust gas cleaning system in July 2024. No damage was found during the subsequent regular six-monthly inspections.

- Cyclone separator renewed in August 2025

- Former gas belt dryers replaced by electrically operated infrared dryers

- Roller performance optimized by installing frequency converters

- Replacement of gas heating with infrared radiators

- Optimization of the heating station's operating mode (Tundish)

- Reduction in energy consumption in electrolysis

- New permit obtained for storage & use of high-purity copper scrap

- Recycling rate optimized

- Recertification of the environmental management system in June 2025

- New permit obtained to increase the amount of dopant material used

Certificates

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

DIN EN ISO 9001 : 2015 | 14001 : 2015 | 50001 : 2018 | 45001 : 2018

PDF

1 MB