Continuous Cast Copper Wire Rod – Aurubis ROD and RheinROD

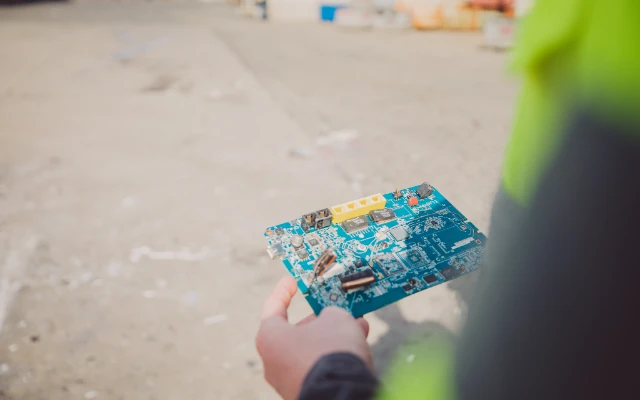

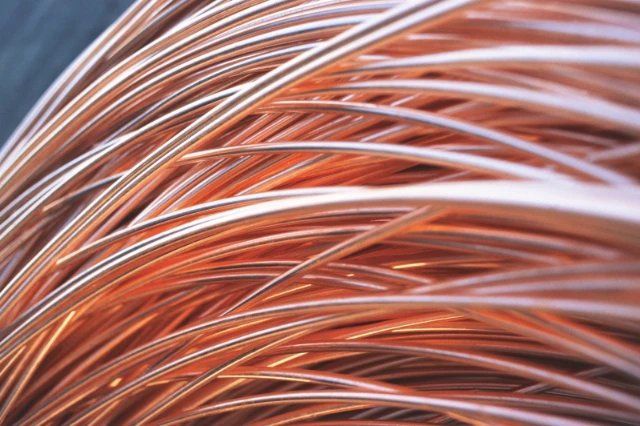

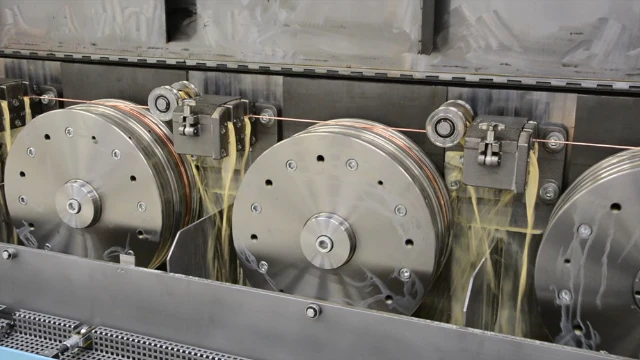

Aurubis ROD | RheinROD is a cast and rolled oxygen-bearing copper wire rod from Aurubis. With its extremely high electrical conductivity, Aurubis ROD ensures the highest possible efficiency in converting and transmitting electrical energy and signals. Other excellent features such as outstanding drawability, uniform recrystallization behavior and excellent surfaces make our wire rod ideally suited for use in demanding processing methods and applications. The basis of these characteristic features of Aurubis ROD | RheinROD is not only its high chemical purity – a result of using cathodes that clearly exceed the LME Grade A quality standard – but also the state-of-the-art production technology at our four ROD plants.

Basis for sophisticated applications

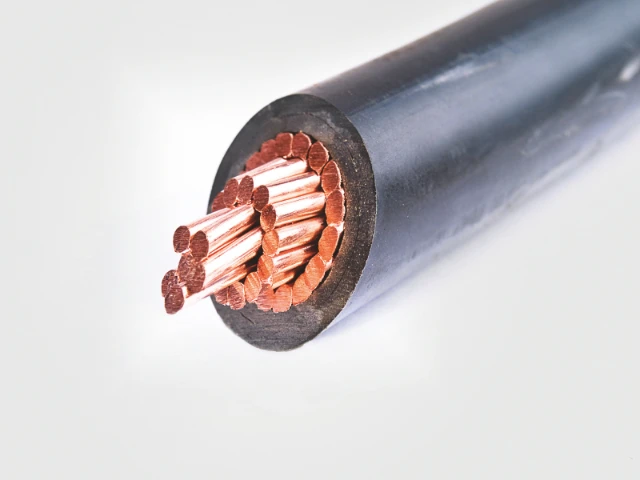

Almost every copper wire – and thus almost every cable or enameled wire – starts out as wire rod, making it the most common copper intermediate in the world. About 75 % of global copper cathode production is processed into continuous cast wire rod. Depending on their intended use, copper wires must meet varying requirements which must be considered when determining the quality of the wire rod. Aurubis supplies the right quality for each application, customer and intended use.

Aurubis ROD | RheinROD is the ideal starting product for further processing by drawing or rolling. The combination of outstanding conductivity and formability makes our ROD the perfect choice for copper wires in various types of cables for infrastructure and enameled copper wires in electrical engineering.

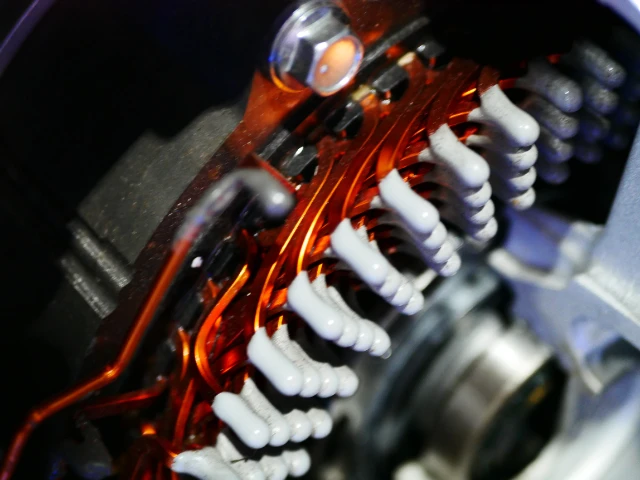

The excellent surface quality of our wire rod, mainly created by production at our four ROD plants, is a basic requirement for high temperature-resistant, error-free insulation systems. For this reason, our production and quality control specialists make surface quality a top priority.

Production capacity

>

per year

Electrical conductivity in % IACS

>

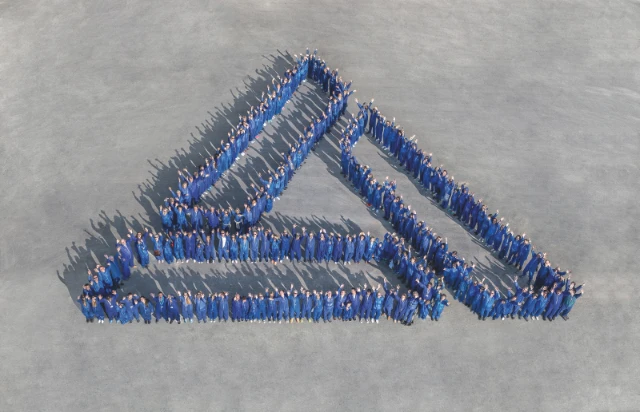

Aurubis ROD lines

Whether in electrical engineering, infrastructure, energy technology, automotive engineering or aviation, in nearly all applications, Aurubis ROD | RheinROD has gained an outstanding reputation in over five decades of production and refinement. Our wire rod is also used in many forward-looking sectors and technologies:

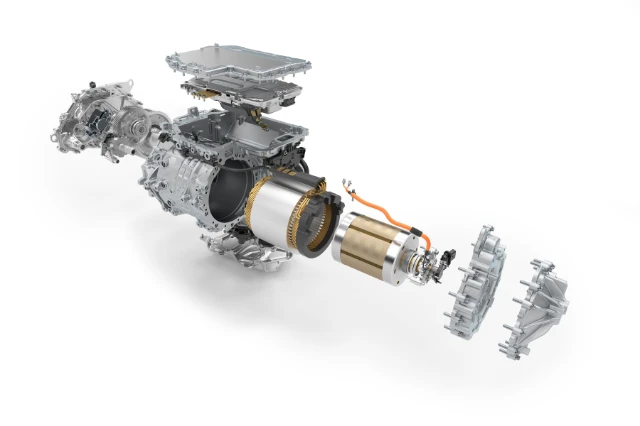

Electromobility

- Aurubis ROD | RheinROD used in traction motors and on-board power supplies

- Use in infrastructure for charging stations, in transformers and charging cables

- Optimization of winding systems in the automotive industry, in transformers and generators

- Ultra-thin insulating layers on flawless copper wire surfaces optimize power densities and reduce energy consumption in traction motors

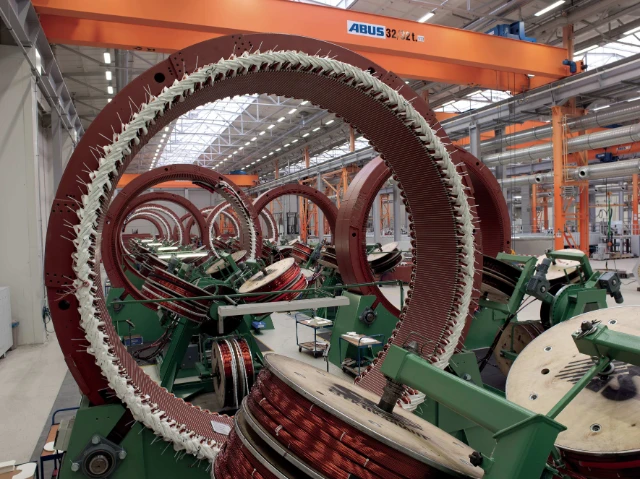

Renewable Energy

- Efficient generation and distribution of CO2-free electrical energy with copper products by Aurubis

- Superior conductivity and pared-down insulation systems enable high energy densities in wind turbine generators

- Transportation to end-user markets through appropriate infrastructure (e.g. extra high voltage underground cables)

- Generation of green energy and significant support of the European Green Deal

In addition to oxygen-bearing copper rod Cu-ETP1, our product portfolio also includes low-alloyed copper rod (CuAg and CuSn) based on oxygen with an interesting combination of high strength and good conductivity. Applications can be found in on-board vehicle power supplies, overhead contact lines and electrical engineering.

Product portfolio

- Designation: Cu-ETP1

- Material number according to DIN EN: CW003A

- Material number according to UNS: C11040

- Oxygen content: 100 - 400 ppm

- Electrical conductivity: > 101 % IACS

- Copper content: 99.99 %

You can find additional information in the product brochure.

- Designation: CuAg0.1 based on Cu-ETP1

- Material number according to DIN EN: CW013A

- Material number according to UNS: C11600

- Silver content: up to 0.12 wt%

- Electrical conductivity: > 100 % IACS

- Copper content: remaining material

You can find additional information in the product brochure.

- Designation: CuSn0.3 based on Cu-ETP1

- Material number according to DIN EN: CW129C

- Tin content: up to 0.3 wt%

- Electrical conductivity: 100 % - 78 % IACS

- Copper content: remaining material

You can find additional information in the product brochure.

Rod diameter

| Cu-ETP1 | CuAg0,1 | CuSn0,3 | |

| 8 mm |

✓ |

✓ | ✓ |

| 10 mm | ✓ | ||

| 12,4 mm | ✓ | ||

| 13 mm | ✓ | ||

|

16 mm |

✓ | ||

| 20 mm | ✓ | ✓ | |

| 23,5 mm | ✓ | ✓ |

Sustainability

CO₂ footprint

in kg CO₂ equivalents per t of wire rod

Already small and still shrinking: The environmental footprint of our products Copper, tin, silver, gold and other metals are the elements at the heart of digitalization. So for sustainable development, it is crucial that we find environmentally friendly ways of producing these essential metals. With our life cycle assessments (LCAs), we have again demonstrated that we are pioneers in sustainability.

3.622 kg

Global Average

2.067 kg

Aurubis ROD | RheinROD

Our biggest impact? Less Impact.

Sustainability excellence: Our certificates and awards

Aurubis is setting new standards for sustainability in the metals and mining industry – third-party verified and internationally recognized.

Recycling and production processes

Aurubis – a customer-oriented partner

Aurubis produces a wide range of metals and semi-finished products and makes an important contribution to the circular economy through multimetal recycling. Supply security is ensured through fully integrated production from anodes to cathodes to copper products. This is also reflected by redundancies with four ROD plants and four tankhouses.

The metal extraction processes at Aurubis are continuously improved so they remain state-of-the-art. We draw on the unique expertise of our specialists in the extraction, processing and recycling of metals and complex compounds.

Aurubis is a solidly positioned MDAX company and is thus a strong, financially sound copper supplier for the long term. We offer customer-specific price hedging solutions with full pricing transparency.

Aurubis offers customers an option called copper on account (Wandelkupfer), which enables them to secure supplies for their own supply chain using copper positions. Customers can flexibly procure copper from Aurubis and provide it to their own suppliers through copper accounts.

For Aurubis, responsible corporate governance is an integral contribution to securing the company's future. The 2030 sustainability targets establish the framework for this purpose. They are a component of the Aurubis corporate strategy and are divided into the focus areas People, Environment, and Economy.

Downloads

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

Product Brochure Aurubis ROD & FOXROD

PDF

2 MB

Dr. Cornel Abratis

Senior Manager Technical Marketing Copper Products

| Phone | +49 40 7883-3062 |