Environmental protection at the Pirdop site

Aurubis Bulgaria is the largest copper producer in southeastern Europe and the second largest company in Bulgaria. Since the Pirdop site was officially opened in 1958, mainly copper anodes, copper cathodes, and sulfuric acid have been produced from primary raw materials.

In the last two decades, the plant has been converted into a highly modern, environmentally friendly operation. Since the acquisition by Aurubis in 2008, more than € 200 million has been invested in modernizing the processes and improving the environmental performance of the site.

Because improving environmental protection remains a very important objective, about 20 % of all investments at the site in the last five years have been allocated to environmental protection projects.

Investments into new, state-of-the-art environmental protection facilities

In the course of the extensive modernization, three significant, state-of-the-art environmental protection facilities have been built in the last several years.

- In November 2014, a new rainwater treatment plant was commissioned. The facility treats rain and drainage water from the 4 km² plant premises in order to continue reducing emissions to water.

- A new additional treatment system for secondary hood off-gases has been in operation since March 2016. The new system utilizes a modern procedure known as Sulfacid technology, which is unique in Bulgaria and in the entire copper smelting industry.

- In addition, a converter slag cooling optimization project (using pot cooling instead of pit cooling) went into regular operation in early 2020. This new facility further reduces the sulfur dioxide emissions and fugitive emissions from the smelting processes. The project will be expanded during the next several years to optimize cooling of the slags from the flash smelting furnace as well. The permit for the expansion was obtained in July 2024 and the construction started in September of the same year. More than 11,000 m² of green areas will also be rehabilitated as part of the project.

- Responsible operations and activities to protect the surrounding environment

Aurubis assumes responsibility for nature conservation. The plant is located near nature conservation areas. The closest are the Tsentralen Balkan buffer, about 1 km away, and Sregdna Gora about 2 km away. Protecting nature and biodiversity is one of our environmental targets, and Aurubis Bulgaria has defined measures to improve the habitat conditions of plants and animals. For example, we have taken the initiative to rehabilitate areas by planting grasses, bushes and trees. Defunct landfill areas on the premises are renatured in the course of their closing. Other environmental projects to reduce emissions likewise have a positive impact on the environment. As an important example, metal emissions to water have been reduced by over 97 % since the year 2000 – and thus improved the rivers’ habitat conditions substantially.

Environmental Stewardship in Action: Effectual management systems, transparent monitoring, and public engagement at the Pirdop Site

Since 2006, Aurubis Bulgaria operates an environmental management system in accordance with the ISO 14001 standard. The last recertification was successfully concluded in March 2024. The external audits carried out as part of the certification of the management system include a review of the environmental data, of the fulfillment of legal provisions, and of the effectiveness of the operating processes. During the second half of 2022, an energy management system (ISO 50001), an occupational health and safety management system (ISO 45001), and a quality management system (ISO 9001) were implemented at the Pirdop site in addition.

The results of the environmental monitoring are transmitted to the authorities. The reports prepared annually can be viewed on the homepage of the Bulgarian Executive Environment Agency.

Since 2011, an information center is operating in Pirdop, which is used by the general public for information purposes. The environmental monitoring data can also be viewed by the public on monitors in the municipalities of Pirdop and Zlatitsa.

The Pirdop site has been part of the EU emission trading scheme since 2008 and has continuously improved its energy efficiency over the years. Aurubis Bulgaria intends to make further investments in environmental measures and energy efficiency improvements in the future as well.

Environmental Protection Pirdop - facts & figures

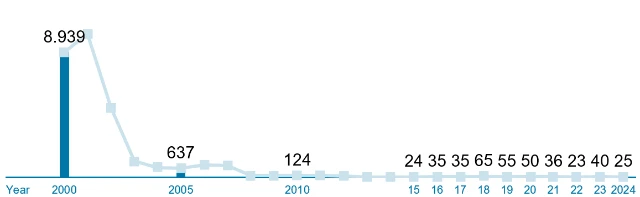

SO2 emissions [kg/t] per ton of copper output

SO2 emissions per ton of copper output have been reduced by 95 % since 2000.

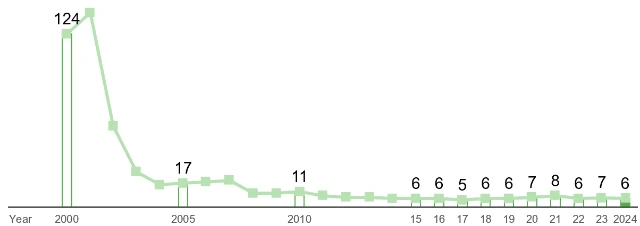

Dust emissions [g/t] per ton of copper output

Dust emissions per ton of copper output have been reduced by 99.5 % since 2000.

Key factors in the reduction of dust and SO2 emissions include:

- a number of modernizations in both lines of the Sulfuric Acid Plant (2001–2014)

- the replacement of the heavy oil dryer with a steam dryer (2001–2002)

- the first (conventional) off-gas cleaning system for secondary hood off-gases (2007)

- the new additional (Sulfacid) off-gas cleaning system for secondary hood off-gases (2016)

- the new facility for cooling converter slag in pots (2020)

- the new facility for cooling flash smelter furnace slag (2024/2025)

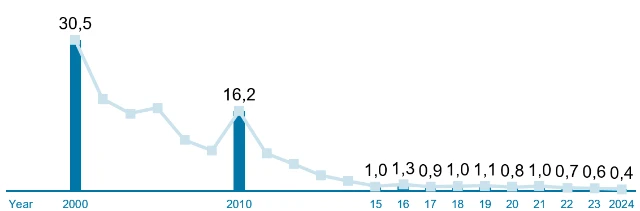

Metal emissions to water per ton of copper output [g/t].

The specific metal emissions to water per ton of copper output have been reduced by 97 % since 2000.

Key factors in the reduction of metal emissions to water include:

- the commissioning of the second and third stages of the treatment plant for industrial wastewater (2005-2006)

- the modernization of the wastewater system for acidic wastewater (2006-2008)

- the modernization of the wastewater systems for domestic sewage (2010-2011) and rainwater (2012-2013)

- the commissioning of the rainwater treatment plant (2014)

- the commissioning of a sand bed filter unit in the industrial wastewater treatment plant (2020)

Due to a new process of the planned upgrade of the wastewater treatment plant at Pirdop site, the amount of sludges for landfilling (generated during production processes in Pirdop) and the chemical consumption will be reduced. This will extend useful lifetime of the landfill for the sludges. Furthermore, the upgrade will increase the WWTP treatment volume capacity for a most efficient wastewater treatment. The construction started in September 2024 and the commissioning is planned in Q1 2026.

Environmental Protection Measures & Projects

Degree of implementation/date/next steps:

- Constructing a new facility for cooling converter slag in pots.

- Building permit received in Feb 2018

- Commissioned in Q1 2020

Status:

- In operation

Degree of implementation/date/next steps:

- Permit obtained in July 2024

- Construction started in September 2024

- Final commissioning is planned by end of 2026

Status:

- Under construction

Degree of implementation/date/next steps

- Installing a new sand bed filter unit in the industrial wastewater treatment plant

- Building permit in 2018

- Commissioned in 2020

Status:

- In operation

Degree of implementation/date/next steps

- First stage commissioning planned for Q2 2026

- Final commissioning including scorodite stage planed by Q1 2027

Status:

- Under construction

Degree of implementation/date/next steps

- Investigation of optimization possibilities finished

- Implementation done during the large-scale facility overhaul in 2019

Status:

- In operation

- Existing bag filters modified and additional filter boxes installed

- Completed - Landfill area renatured in 2021

Construction of a series of photovoltaic power plants (PVP)

Degree of implementation:

- PVP-1: Signed agreement with CEZ ESCO Bulgaria for the construction of the photovoltaic power plant (10 MW) on a territory of historical remediated landfill; commissioned in March 2023.

- PVP 2/3: Construction started in April 2024

- PVP 4: Planning completed, approval received

Status:

- PVP1: Completed. The solar power plant was commissioned in March 2023

- PVP2: Commissioning planned for Q1 2026

- PVP3: Commissioned in Q4 2024

- PVP4: Start of construction activities planned for summer 2026

Environmental Protection milestones at Pirdop site

Aurubis‑1 Solar Farm: In July 2020, a contract was signed with CEZ ESCO Bulgaria EOOD. The Aurubis‑1 photovoltaic system at the Pirdop site reduces external electricity consumption by 11,000 MWh per year, equivalent to the annual needs of approximately 3,500 households or a city with 14,000 inhabitants. Compared to coal-based power generation, this results in annual CO₂ reductions of 15,000 tons.

As part of our long-term strategy ‘Metals for Progress: Driving Sustainable Growth’ we began construction of two additional photovoltaic parks in April 2024. An additional expansion has already been approved. Since 2021, the captive solar park has been continuously expanded as part of ongoing investments to decarbonize production. And we continue following this path with the construction of the fourth photovoltaic power plant, which is scheduled to begin in summer 2026.

With the phased expansion of on-site solar power generation, Aurubis is significantly increasing captive electricity production. Once fully implemented, four photovoltaic plants are expected to cover around 15% of the site’s electricity demand with green energy. Total annual electricity generation is expected to amount to approximately 55,000 MWh, corresponding to the electricity needs of a city with around 25,000 inhabitants. This will result in annual CO₂ savings of around 25,000 tons.

A new facility for cooling converter slag in pots was commissioned in early 2020. In the following years, the project was expanded to also optimize the cooling process of flash smelter furnace slag.

A new sand bed filter unit was installed to reduce the discharge of undissolved substances into receiving water bodies.

Expansion of the Fayalite Landfill:

The first stage of the landfill expansion was completed in May 2018. The project comprises two cells with a total capacity of approximately 19.8 million tons. The cells are surrounded by soil embankments, equipped with insulation and drainage systems to ensure environmental protection.

Sulfuric Acid Terminal at the Port of Burgas:

A new terminal for handling and storing sulfuric acid was inaugurated at the Port of Burgas on the Black Sea, providing a total storage capacity of 50,000 tons. The project was implemented in cooperation with BMF Port Burgas.

Warehouse for Copper Raw Materials:

A new enclosed warehouse with a storage capacity of 65,000 tons of copper concentrates opened at BMF Port Burgas. The project focuses on improving air protection by enabling loss-free handling and storage using best available techniques (BAT).

Seveso‑III Permit Issued:

In August 2017, Aurubis Bulgaria successfully received the Seveso permit pursuant to EU Directive 2012/18/EU.

Sludge Landfills:

The third sludge landfill was successfully closed in compliance with all environmental requirements and is now subject to long-term monitoring. At the same time, the fourth sludge landfill was constructed and commissioned with all relevant environmental requirements (in particular Directive 1999/31/EC)

A new additional treatment plant for secondary hood off-gases (Sulfacid) was constructed and commissioned. The technology is unique in Bulgaria and represents a significant contribution to environmental protection in the copper smelting industry.

A rainwater and drainage water treatment plant with a capacity of 250 m³/h was opened. Total investments amounted to €6.3 million. The facility treats runoff from a site area of 4 km² and sustainably reduces emissions to water in accordance with BAT standards.

With EU funding support, a project was implemented to reuse residues and introduce fayalite (fine‑grained iron silicate) as a new product. Investments in new equipment expanded the utilization options for this by-product.

The investment program, with a total volume of €44.2 million (including €26 million for environmental protection), aimed to improve the environmental performance and efficiency of smelting operations through extensive technical upgrades.

The renovated flotation plant for slag was reopened, increasing both processing capacity and copper recovery rates while applying best available techniques.

New Tankhouse:

A new tankhouse equipped with fully automated, state‑of‑the‑art technology was commissioned. With total costs of €82 million, it represented the largest industrial investment in Bulgaria at that time.

Off-Gas Treatment:

The first conventional treatment system for secondary hood off-gases was commissioned, significantly reducing dust and sulfur dioxide emissions.

Sludge Landfill: In addition, the third sludge landfill was constructed in compliance with the highest safety standards.

The environmental management system at the Pirdop site was certified according to ISO 14001 for the first time.

The second and third stages of the industrial wastewater treatment plant were commissioned. In parallel, the sulfuric acid plant was upgraded, and the site received the permit under the EU IPPC Directive.

The successful completion of the environmental remediation program in Pirdop was distinguished with the 2003/2004 Belgian environmental protection prize in the category “International Cooperation for Sustainable Development.”

In addition, the second sludge landfill was constructed.

A dedicated landfill for fayalite from the flotation process was built in compliance with all environmental requirements. Subsequent expansions were completed in 2009 and 2015.

Environmental remediation program: The “Georgi Damyanov” smelter was operated as a state-owned company from 1958 to 1997. Due to inadequate investments in environmental protection by the Bulgarian government, there were considerable environmental impacts in the region during this time. The company was privatized in 1997 and managed by the Belgian Union Minière Group from that point. The privatization agreement included a remediation program amounting to US$ 25 million, among other things. Within the scope of this program, defunct facilities were torn down, building rubble was appropriately disposed of, and landfill areas (the sludge settling pond known as the “Blue Lagoon,” the fayalite landfill, the slag landfill) and contaminated soil were rehabilitated. In the course of the remediation program, the first stage of the treatment plant for industrial wastewater and the first landfill for sludge from wastewater and off-gas treatment were built and commissioned in 1999.

Certificates Aurubis Bulgaria

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

ISO 9001: 2015

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

ISO 14001: 2015

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

ISO 45001 : 2018

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

ISO 50001 : 2018

PDF

2 MB

Ange Kostov

Environmental Department Manager

| Phone | +359 728 62-203 |

| Mobile | +359 885 350 284 |

Krasimir Slavov

Enviromental Department Operational Manager

| Phone | +359 728 62-514 |

| Mobile | +359 887 707 524 |