Umweltschutz am Standort Pirdop

Aurubis Bulgarien ist der größte Kupferproduzent Südosteuropas und das zweitgrößte Unternehmen des Landes. Seit der offiziellen Eröffnung des Standortes in Pirdop im Jahr 1958 werden hier hauptsächlich Kupferanoden, Kupferkathoden und Schwefelsäure aus Primärrohstoffen produziert.

In den letzten zwei Jahrzehnten wurde das Werk zu einem hochmodernen und umweltfreundlichen Betrieb umgebaut. Seit der Übernahme durch Aurubis im Jahr 2008 wurden mehr als 200 Millionen Euro in die Modernisierung der Prozesse und die Verbesserung der Umweltbilanz des Standorts investiert.

Da die Verbesserung des Umweltschutzes nach wie vor ein sehr wichtiges Ziel ist, wurden in den letzten fünf Jahren etwa 20 % aller Investitionen am Standort für Umweltschutzprojekte aufgewendet.

Investitionen in neue Umweltschutzanlagen auf dem neuesten Stand der Technik

Im Zuge der umfassenden Modernisierungen wurden in den letzten Jahren insbesondere drei bedeutende Umweltschutzanlagen gebaut, die dem neuesten Stand der Technik entsprechen.

- Eine neue Regenwasseraufbereitungsanlage wurde im November 2014 in Betrieb genommen. Die Anlage behandelt Regen- und Drainagewasser aus dem 4 km² großen Werksgelände, um die Emissionen in Gewässer weiter zu reduzieren.

- Eine neue zusätzliche Behandlungsanlage für Sekundärhaubenabgase ist seit März 2016 in Betrieb. Die neue Anlage nutzt ein modernes Verfahren, das als Sulfacid-Technologie bekannt ist und in Bulgarien und in der gesamten Kupferhüttenindustrie einzigartig ist.

- Darüber hinaus wurde ein Projekt zur Optimierung der Kühlung von Konverterschlacken (mit Topfkühlung anstelle von Grubenkühlung) Anfang 2020 in den regulären Betrieb genommen. Diese neue Anlage reduziert die Schwefeldioxidemissionen und diffusen Emissionen aus den Verhüttungsprozessen weiter. Das Projekt wird in den nächsten Jahren erweitert, um auch die Kühlung der Schlacken aus dem Schwebeschmelzofen zu optimieren. Die Genehmigung für die Erweiterung wurde im Juli 2024 erteilt, und die Bauarbeiten begannen im September desselben Jahres. Im Rahmen des Projekts werden auch mehr als 11.000 m² Grünflächen saniert.

Verantwortungsbewusster Betrieb und Aktivitäten zum Naturschutz

Aurubis übernimmt Verantwortung für den Naturschutz. Das Werk befindet sich in der Nähe von Naturschutzgebieten. Am nächsten liegen das Tsentralen Balkan-Puffergebiet in etwa 1 km Entfernung und Sregdna Gora in etwa 2 km Entfernung. Der Schutz der Natur und der Biodiversität ist eines unserer Umweltziele, und Aurubis Bulgarien hat Maßnahmen zur Verbesserung der Lebensbedingungen von Pflanzen und Tieren definiert. So haben wir beispielsweise die Initiative ergriffen, Flächen durch das Anpflanzen von Gräsern, Sträuchern und Bäumen zu wiederherzustellen. Stillgelegte Deponien auf dem Gelände werden im Zuge ihrer Schließung renaturiert. Andere Umweltprojekte zur Emissionsreduzierung wirken sich ebenfalls positiv auf die Umwelt in der Umgebung aus. Ein wichtiges Beispiel: Die Metallemissionen in Gewässer wurden seit dem Jahr 2000 um über 97 % reduziert – und damit die Lebensbedingungen in den Flüssen erheblich verbessert.

Umweltverantwortung in der Praxis: Wirksame Managementsysteme, transparente Überwachung und öffentliches Engagement am Standort Pirdop

Seit dem Jahr 2006 führt Aurubis Bulgarien ein Umweltmanagementsystem nach der Norm ISO 14001. Die letzte Rezertifizierung wurde im März 2024 erfolgreich abgeschlossen. Die im Rahmen der Zertifizierung des Managementsystems durchgeführten externen Audits umfassen eine Überprüfung der Umweltdaten, der Einhaltung gesetzlicher Vorschriften und der Wirksamkeit der Betriebsprozesse. In der zweiten Jahreshälfte 2022 wurden am Standort Pirdop zudem ein Energiemanagementsystem (ISO 50001), ein Arbeitsschutzmanagementsystem (ISO 45001) und ein Qualitätsmanagementsystem (ISO 9001) eingeführt.

Die Ergebnisse der Umweltüberwachung werden an die Behörden weitergeleitet. Die jährlich erstellten Berichte können auf der Homepage der bulgarischen Exekutivagentur für Umwelt eingesehen werden.

Seit 2011 gibt es in Pirdop ein Informationszentrum, das von der Öffentlichkeit zu Informationszwecken genutzt wird. Die Umweltüberwachungsdaten können auch von der Öffentlichkeit auf Monitoren in den Gemeinden Pirdop und Zlatitsa eingesehen werden.

Der Standort Pirdop ist seit 2008 Teil des EU-Emissionshandelssystems und hat seine Energieeffizienz im Laufe der Jahre kontinuierlich verbessert. Aurubis Bulgarien strebt auch in Zukunft weitere Investitionen in Umweltmaßnahmen und Energieeffizienzverbesserungen an.

Umweltschutz Pirdop - Daten & Fakten

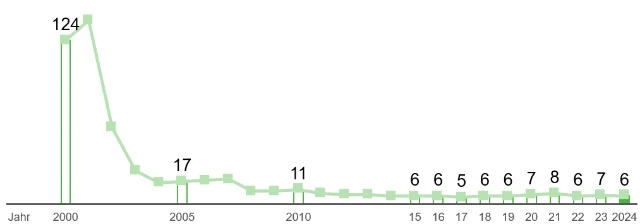

SO2-Emissionen [kg/t] pro erzeugter Tonne Kupfer

Die SO2-Emissionen pro erzeugter Tonne Kupfer konnten seit dem Jahr 2000 um 95 % reduziert werden.

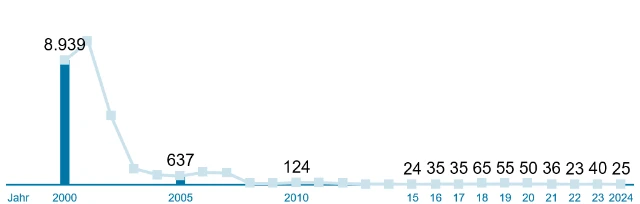

Staubemissionen [kg/t] pro erzeugter Tonne Kupfer

Die Staubemissionen pro erzeugter Tonne Kupfer konnten seit dem Jahr 2000 um 99,5 % reduziert werden.

Maßgeblich für die Reduzierung der Emissionen waren:

- zahlreiche Modernisierungen beider Stränge der Schwefelsäureanlage (2001 - 2014)

- der Ersatz der Schweröltrockner durch Dampftrockner (2001 – 2002)

- das erste (konventionelle) Abgasreinigungssystem für Sekundärhaubenabgase (2007)

- das neue zusätzliche (Sulfacid) Abgasreinigungssystem für Sekundärhaubenabgase (2016).

- die neue Anlage zur Kühlung von Konverterschlacke in Töpfen (2020)

- die neue Anlage zur Kühlung von Schwebeschmelzofenschlacke (2024/2025)

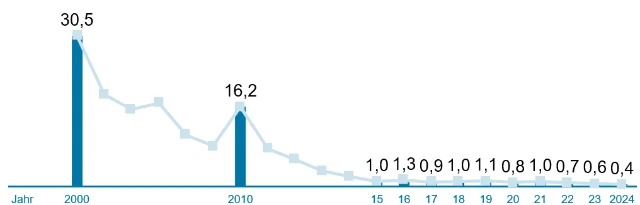

Metallemissionen in Gewässer pro Tonne Kupferproduktion [g/t]

Die spezifischen Metallemissionen in Gewässer pro Tonne Kupferproduktion wurden seit 2000 um 97 % reduziert.

Zu den wichtigsten Faktoren für die Reduzierung der Metallemissionen in Gewässer zählen:

- die Inbetriebnahme der zweiten und dritten Stufe der Behandlungsanlage für Industrieabwässer (2005–2006)

- die Modernisierung des Abwassersystems für saures Abwasser (2006–2008)

- die Modernisierung der Abwassersysteme für Haushaltsabwasser (2010–2011) und Regenwasser (2012–2013)

- die Inbetriebnahme der Aufbereitungsanlage für Regenwasser (2014)

- die Inbetriebnahme eines Sandbettfilters in der in der Anlage zur Reinigung von Prozessabwasser (2020)

- Modernisierung der Anlage zur Reinigung von Prozessabwasser (2024–2027)

- Erste Phase – Inbetriebnahme für das zweite Quartal 2026 geplant

- Letzte Phase – Inbetriebnahme für das 1. Quartal 2027 geplant

Durch ein neues Verfahren bei der geplanten Modernisierung der Abwasserbehandlungsanlage am Standort Pirdop werden die Menge der bei den Produktionsprozessen in Pirdop anfallenden Schlämme, die auf Deponien entsorgt werden müssen, und der Chemikalienverbrauch reduziert. Dadurch verlängert sich die Nutzungsdauer der Deponie für die Schlämme. Darüber hinaus wird durch die Modernisierung die Kapazität der Abwasserbehandlunganlage erhöht, um eine möglichst effiziente Abwasserbehandlung zu erreichen. Die Bauarbeiten begannen im September 2024, und die erste Phase der Umrüstung soll voraussichtlich vor Mitte 2026 endgültig in Betrieb genommen werden. Die zweite und letztePhase soll spätestens Anfang 2027 endgültig in Betrieb genommen werden.

Maßnahmen & Projekte im Umweltschutz

Umsetzungsgrad/Datum/nächste Schritte:

- Bau einer neuen Anlage zur Kühlung von Konverterschlacke in Töpfen.

- Baugenehmigung im Februar 2018 erhalten

- Inbetriebnahme Angang 2020

Status:

- In Betrieb

Umsetzungsgrad/Datum/nächste Schritte:

- Genehmigung im Juli 2024 erhalten

- Baubeginn im September 2024

- Die endgültige Inbetriebnahme ist für Ende 2026 geplant

Status:

- Im Bau

Umsetzungsgrad/Datum/nächste Schritte

- Installation einer neuen Sandbettfiltereinheit in der Behandlungsanlage für Prozessabwasser

- Baugenehmigung im Jahr 2018

- Inbetriebnahme im Jahr 2020

Status:

- In Betrieb

Umsetzungsgrad/Datum/nächste Schritte

- Inbetriebnahme der ersten Stufe für das zweite Quartal 2026 geplant

- Endgültige Inbetriebnahme einschließlich Scorodite-Phase für das 1. Quartal 2027 geplant

Status

- Im Bau

Umsetzungsgrad/Datum/nächste Schritte

- Untersuchung der Optimierungsmöglichkeiten abgeschlossen

- Umsetzung während der groß angelegten Anlagenüberholung im Jahr 2019

Status

- In Betrieb

- Vorhandene Schlauchfilter modifiziert und zusätzliche Filterkästen installiert

Status:

- Abgeschlossen – Deponiegelände wurde im Jahr 2021 renaturiert

Bau einer Reihe von Photovoltaik-Anlagen (photovoltaic power plants, PVP)

Umsetzungsgrad:

- PVP-1: Unterzeichnung einer Vereinbarung mit CEZ ESCO Bulgaria über den Bau eines Photovoltaik-Kraftwerks (10 MW) auf dem Gelände einer sanierten Deponie; Inbetriebnahme im März 2023.

- PVP 2/3: Baubeginn im April 2024

- PVP 4: Planung abgeschlossen, Genehmigung erhalten

Status:

- PVP1: Abgeschlossen. Das Solarkraftwerk wurde im März 2023 in Betrieb genommen.

- PVP2: Inbetriebnahme für das 1. Quartal 2026 geplant

- PVP3: Inbetriebnahme im 4. Quartal 2024

- PVP4: Baubeginn für Sommer 2026 geplant

Meilensteine im Umweltschutz am Standort Pirdop

Solarpark Aurubis-1: Im Juli 2020 wurde ein Vertrag mit CEZ ESCO Bulgaria EOOD unterzeichnet. Die Photovoltaikanlage Aurubis-1 am Standort Pirdop reduziert den externen Stromverbrauch um 11.000 MWh pro Jahr, was dem Jahresbedarf von etwa 3.500 Haushalten oder einer Stadt mit 14.000 Einwohnern entspricht. Im Vergleich zur Stromerzeugung aus Kohle ergibt sich daraus eine jährliche CO₂-Einsparung von 15.000 Tonnen.

Im Rahmen unserer langfristigen Strategie „Metals for Progress: Driving Sustainable Growth“ haben wir im April 2024 mit dem Bau von zwei weiteren Photovoltaikparks begonnen. Eine weitere Erweiterung wurde bereits genehmigt. Seit 2021 wird der firmeneigene Solarpark im Rahmen laufender Investitionen zur Dekarbonisierung der Produktion kontinuierlich ausgebaut. Diesen Weg setzen wir mit dem Bau der vierten Photovoltaikanlage fort, der im Sommer 2026 beginnen soll.

Mit dem schrittweisen Ausbau der Solarstromerzeugung vor Ort erhöht Aurubis die Eigenstromproduktion deutlich. Nach vollständiger Umsetzung sollen vier Photovoltaikanlagen rund 15 % des Strombedarfs des Standorts mit grüner Energie decken. Die jährliche Stromerzeugung wird voraussichtlich insgesamt etwa 55.000 MWh betragen, was dem Strombedarf einer Stadt mit rund 25.000 Einwohnern entspricht. Dies wird zu einer jährlichen CO₂-Einsparung von rund 25.000 Tonnen führen.

Anfang 2020 wurde eine neue Anlage zur Kühlung von Konverterschlacke in Töpfen in Betrieb genommen. In den folgenden Jahren wurde das Projekt erweitert, um auch den Kühlprozess von Schlacken aus dem Schwebeschmelzofen zu optimieren.

Es wurde eine neue Sandbettfiltereinheit installiert, um die Einleitung ungelöster Stoffe in die aufnehmenden Gewässer zu reduzieren.

Erweiterung der Fayalite-Deponie:

Die erste Phase der Deponieerweiterung wurde im Mai 2018 abgeschlossen. Das Projekt umfasst zwei Zellen mit einer Gesamtkapazität von ca. 19,8 Millionen Tonnen. Die Zellen sind von Erddeichen umgeben, die mit Isolierungs- und Entwässerungssystemen ausgestattet sind, um den Umweltschutz zu gewährleisten.

Schwefelsäureterminal im Hafen von Burgas:

Im Hafen von Burgas am Schwarzen Meer wurde ein neues Terminal für den Umschlag und die Lagerung von Schwefelsäure mit einer Gesamtlagerkapazität von 50.000 Tonnen eingeweiht. Das Projekt wurde in Zusammenarbeit mit BMF Port Burgas umgesetzt.

Lager für Kupferrohstoffe:

Im BMF Port Burgas wurde ein neues geschlossenes Lager mit einer Lagerkapazität von 65.000 Tonnen Kupferkonzentraten eröffnet. Das Projekt konzentriert sich auf die Verbesserung des Luftschutzes durch verlustfreies Handling und Lagerung unter Verwendung der besten verfügbaren Techniken (BVT).

Seveso-III-Genehmigung erteilt:

Im August 2017 erhielt Aurubis Bulgaria erfolgreich die Seveso-Genehmigung gemäß der EU-Richtlinie 2012/18/EU.

Schlammdeponien:

Die dritte Schlammdeponie wurde unter Einhaltung aller Umweltanforderungen erfolgreich geschlossen und unterliegt nun einer langfristigen Überwachung. Gleichzeitig wurde die vierte Schlammdeponie unter Einhaltung aller relevanten Umweltanforderungen (insbesondere der Richtlinie 1999/31/EG) gebaut und in Betrieb genommen.

Eine neue, zusätzliche Aufbereitungsanlage für Sekundärhaubenabgase wurde gebaut und in Betrieb genommen. Die Technologie ist einzigartig in Bulgarien und leistet einen bedeutenden Beitrag zum Umweltschutz in der Kupferhüttenindustrie.

Eröffnung einer Regenwasseraufbereitungsanlage: Die von Aurubis getätigten Gesamtinvestitionen für die Behandlungsanlage für Regen- und Drainagewasser belaufen sich auf 6,3 Mio. €. Die Bauphase erstreckte sich über ein Jahr und umfasste den Bau der Anlage mit einer Kapazität von 250 m³/h und Auffangbecken für anfallende Abwässer. Um die Emissionen in Wasser nachhaltig zu senken, reinigt die Anlage das Regen- und Drainagewasser des Geländes, das eine Fläche von 4 km² aufweist. Die Anlage entspricht der besten verfügbaren Technik (BVT).

Mit finanzieller Unterstützung der EU wurde ein Projekt zur Nutzung von Reststoffen und zur Einführung von Fayalit (feinkörniges Eisensilikat) als neues Produkt umgesetzt. Investitionen in neue Anlagen erweiterten die Verwendungsmöglichkeiten für dieses Nebenprodukt.

Das Investitionsprogramm mit einem Gesamtvolumen von 44,2 Millionen Euro (davon 26 Millionen Euro für den Umweltschutz) zielte darauf ab, die Umweltleistung und Effizienz der Schmelzbetriebe durch umfangreiche technische Modernisierungen zu verbessern.

Die renovierte Flotationsanlage für Schlacke wurde wieder in Betrieb genommen, wodurch sowohl die Verarbeitungskapazität als auch die Kupferausbeute gesteigert und gleichzeitig die besten verfügbaren Techniken angewendet wurden.

Neue Kupferelektrolyse: Eine neue Kupferelektrolyse mit vollautomatischer, modernster Technologie wurde in Betrieb genommen. Mit Gesamtkosten von 82 Millionen Euro war dies die größte Industrieinvestition in Bulgarien zu dieser Zeit.

Abgasbehandlung: Das erste konventionelle Behandlungssystem für Sekundärhaubenabgase wurde in Betrieb genommen, wodurch die Staub- und Schwefeldioxidemissionen deutlich reduziert wurden.

Schlammdeponie: Darüber hinaus wurde die dritte Schlammdeponie unter Einhaltung höchster Sicherheitsstandards errichtet.

Das Umweltmanagementsystem am Standort Pirdop wurde erstmals nach ISO 14001 zertifiziert.

Die zweite und dritte Stufe der Behandlungsanlage für Prozessabwasser wurden in Betrieb genommen. Parallel dazu wurde die Schwefelsäureanlage modernisiert und der Standort erhielt die Genehmigung gemäß der EU-IVU-Richtlinie.

Die erfolgreiche Vollendung des Umweltsanierungsprogramms in Pirdop wurde mit dem belgischen Umweltschutzpreis 2003/2004 in der Kategorie „Internationale Zusammenarbeit für nachhaltige Entwicklung“ ausgezeichnet.

Darüber hinaus wurde die zweite Schlammdeponie errichtet.

Eine spezielle Deponie für Fayalit aus dem Flotationsprozess wurde unter Einhaltung aller Umweltanforderungen errichtet. Weitere Erweiterungen wurden 2009 und 2015 abgeschlossen.

Umweltsanierungsprogramm: Das Hüttenwerk „Georgi Damyanov“ wurde von 1958 bis 1997 als staatseigenes Unternehmen betrieben. Wegen unzulänglicher Investitionen in den Umweltschutz seitens des bulgarischen Staats kam es in dieser Zeit in der Region zu erheblichen Auswirkungen auf die Umwelt. 1997 wurde das Unternehmen privatisiert und seitdem von der belgischen Union Minière Group geführt. Der Vertrag zur Privatisierung beinhaltete unter anderem ein Sanierungsprogramm im Umfang von 25 Mio. US$. Im Rahmen dieses Programms wurden stillgelegte Anlagen abgerissen, der Bauschutt fachgerecht entsorgt und Deponieflächen (der Schlammteich, auch bekannt als „Blaue Lagune“, die Fayalitdeponie, die Schlackedeponie) sowie kontaminiertes Erdreich saniert. Im Rahmen des Sanierungsprogrammes wurden 1999 auch die erste Stufe der Behandlungsanlage für industrielle Abwässer und die erste Deponie für Schlämme aus der Abwasser- und Abgasbehandlung errichtet und in Betrieb genommen.

Zertifikate Aurubis Bulgaria

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

ISO 9001: 2015

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

ISO 14001: 2015

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

ISO 45001 : 2018

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

ISO 50001 : 2018

PDF

2 MB

Angel Kostov

Umweltmanager

| Telefon | +359 728 62-203 |

| Mobil | +359 885 350 284 |

Krasimir Slavov

Umweltmanager Operations

| Telefon | +359 728 62-514 |

| Mobil | +359 887 707 524 |