Environmental protection at Aurubis Buffalo

Aurubis Buffalo, located in the state of New York, is about a half-hour away from Niagara Falls by car. Copper products have been fabricated here since 1906.

The completely integrated plant with approximately 580 employees includes a copper and brass foundry, a hot rolling mill and cold rolling mills, a number of annealing furnaces, and a number of longitudinal slitting machines to produce strips with a variety of copper alloys, for example for connectors, and telecommunications and electrical applications. In 2003, the plant became the first rolling mill for copper alloys in North America to earn TS 16949 certification, a quality management certificate based on ISO 9001. The investment program to modernize the plant is continuously updated.

Aurubis Buffalo operates environmental protection facilities in order to minimize emissions and to protect nature. All foundry off-gases pass through control devices (baghouses) and dedicated filters prior to entering the atmosphere. Resulting filter dust that accumulates in the process is collected and subsequently sold to a third party as a substitute for mining raw zinc. The acidic rinse water from the copper/alloy cleaning operation is neutralized and treated in the company’s on-site treatment plant, which has been significantly upgraded and improved in recent years. The filter cake produced in the waste treatment plant still contains valuable metals and is therefore sent off for metal recovery. Ninety-six percent (96%) of the electricity consumed is obtained from a renewable power source, the Niagara Falls hydroelectrical generation plant, and other renewal sources.

One key milestone was the introduction of an environmental, occupational health and safety (OH&S), and energy management systems in accordance with ISO 14001, 45001, & 50001. The management systems were successfully implemented in 2022.

The Aurubis Buffalo site has been working jointly with the environmental team to increase education and awareness of chemical exposure; handling chemicals; managing hazardous and non-hazardous waste; process improvements to reduce waste generation; and environmental compliance requirements. Aurubis Buffalo ensures that the plant is compliant with federal and state regulatory requirements and laws.

We are continually raising awareness of new and changing environmental regulations through an education program that all employees participate in, which includes executive management and hourly workers to ensure that all employees at Aurubis Buffalo are aware of federal and state regulatory systems.

Beyond the central environmental targets, additional activities were carried out for the benefit of the employees and the environment during the reporting period. These included:

- Continually re-evaluating the plant and processes waste reduction for potential opportunities

- Upgrades at the Aurubis wastewater treatment plant have included:

- Sludge press and pump rebuilt

- Clarifier rebuilt

- Programmable logic controller (PLC) upgrade

- Caustic pumps upgraded

- Enhanced instrumentation

- New sand filter

- Expanded containment area for acid storage

- New building to house sand filter and containment area

- New electrical control system and motor control center.

Environmental Protection Buffalo – facts & figures

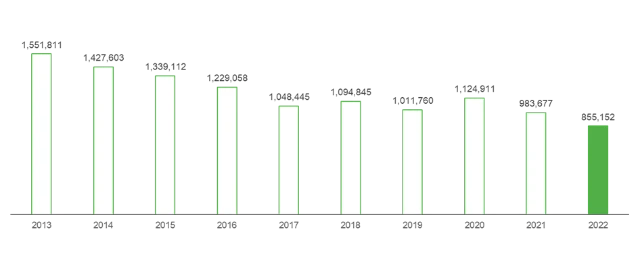

Water withdrawal from municipal source [m³]

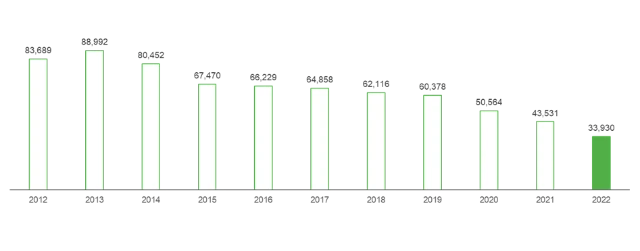

CO2 emissions [t CO2]

Current environmental targets and measures

Description:

- Comprehensive survey of all sewer drains for potential risk of unintended discharge to the publicly owned treatment work (POTW). 128 sewer drains identified and appropriate actions taken.

Status:

- Complete (2021)

Description:

-

Wastewater treatment plant upgrades to improve efficiency and automation

Status:

-

Complete (2022)

Description:

-

Upgrades to containment & transfer areas

Status:

-

Complete (2022)

Description:

-

Upgrades to the delivery systems & containment moat.

Status:

-

Complete (2022)

Description:

-

An engineering firm has been retained to evaluate the process and make design recommendations for the basic baghouse system layout/solution and baghouse capacity.

Status:

-

Ongoing

Description:

-

Evaluating potential projects to decrease CO2 emissions by 50% by 2030 based on 2018 emissions.

Status:

-

Ongoing

Description:

-

Risk assessments by external consultants conducted annually to assess new and potential future regulatory changes impacting the facility.

Status:

-

Ongoing

Environmental Policy

We have established this Environmental Policy to be consistent with the purpose and context of our organization. It provides a framework for the setting and review of environmental objectives in addition to our commitment to the following:

- Protect the environment, including preventing pollution

- Management of waste streams

- Conform to applicable legislative, regulatory and compliance obligations

- Continually improve our environmental management system and to enhance environmental performance

Occupational Health & Safety Policy

We have established this OH&S policy to be consistent with the purpose and context of our organization. It provides a framework for the setting and review of objectives in addition to our commitment to satisfy applicable regulatory, legislative and other requirements, as well as our commitment to continually improve our management system.

We are committed to:

- Providing safe and healthy working conditions to prevent work-related injuries and ill health appropriate to the nature of the OH&S risks to which workers and others are exposed;

- Provide a framework for setting our OH&S objectives;

- Fulfilling our legal and other requirements;

- Eliminating hazards and reducing OH&S risks;

- Continual improvement of the OH&S management system;

- Consulting and participating with workers, and, where they exist, workers’ representatives on OH&S issues.

Energy Policy

Aurubis (‘the Organization’) recognizes that the management of energy use is key to its business development and performance and is therefore an integral part of its business strategy policy.

The Organization shall provide effective energy management throughout its activities and have established this Energy Policy to be consistent with the purpose and context of our Organization. It provides a framework for the setting and review of energy objectives and targets in addition to our commitment to the following.

We shall:

- Provide and make information and necessary resources available for review and to ensure the achievement of energy objectives and targets.

- Ensure that procurement activities considers the supply of energy efficient products and services.

- Conform to applicable legislative, regulatory, and compliance obligations.

- Where design activities form part of our management process, consider energy performance improvement at all stages.

- Continually improve our energy management system and to enhance energy performance.

David Bissonette

Director Environmental, Health, & Safety

| Phone | +1 716 879 6754 |

| Mobile | +1 716 879 6708 |