Environmental protection at Lünen

With a production capacity of up to 210,000 t of copper cathodes per year, the plant, which is just one kilometer away from Lünen Town Hall, is one of the world’s largest secondary copper smelters. Around 660 employees produce copper anodes, copper cathodes, iron silicate sand, and a variety of co-products here on the 316,000 m³ premises.

The site has capabilities for flexible secondary raw material use and, as a multimetal recycling site, is able to process highly complex raw materials in its own smelting and refining processes.

In addition to traditional recycling materials such as scrap copper, alloy scrap, sludges, and industrial residues, recycling raw materials also include complex materials such as processed fractions from waste electrical and electronic equipment and end‑of‑life vehicles, as well as non‑ferrous metal fractions recovered from municipal waste incineration ash.

Improvements and investments in environmental protection are also of great importance in Lünen. Around € 145 million has been invested in environmental protection since 2000.

With the commissioning of the Kayser Recycling System at the Lünen site in 2002, the Aurubis Group became one of the world’s largest copper recyclers and set new industry‑leading standards in environmental protection.

In the subsequent years, many more investments were made in environmental protection, especially to reduce fugitive emissions in the metallurgical facilities and in the storage and handling of input materials.

Efficient water management through a new process‑water system and a new water concept

But the Lünen site is continuously developing its approach to water as well. The facility for water retention, treatment and use of surface water — abbreviated as the RAN facility — operated with a total investment volume of around € 4.5 million enables more than 120,000 m³ of treated rainwater to be used for internal purposes as process water and thus saved every year. The plant is improved continuously. Optimized water collection and delivery has already reduced the amount of water withdrawal by 20 % compared to 2019. To further improve sustainable water use, new optimizations of internal water use are planned for the Lünen site in the coming years as part of a water concept. The aim is to use all water internally as far as possible and to avoid discharging wastewater into the public sewer system.

Expanded waste‑heat utilization and modernized electrolysis increase energy efficiency

The efficient use of natural resources has been part of Aurubis' corporate culture for many years and is also an important part of ecological and economic responsibility for the Lünen site.

The efficient use of natural resources also includes energy and the reduction of CO₂ emissions. Innovative projects to increase energy efficiency ensure highly efficient and flexible power generation from waste heat at the Lünen site by means of cogeneration via a two-stage condensing turbine. Up to 23 million kWh of electricity - this corresponds to approximately 15% of the site’s electricity demand or the average annual electricity consumption of around 7,000 three‑person households - can be generated and at the same time up to 14,000 t of CO₂ avoided each year.

The Lünen site supplies its equipment and facilities with its own steam, primarily from smelting furnace waste heat and — if not enough waste heat is available — additional boilers using oil and gas. The steam generated is fed into the local network to cover process steam needs. Due to process-related fluctuations, the waste heat supply isn’t continuous. To eliminate this discontinuity and reduce the use of fossil fuels, Aurubis AG expanded the steam infrastructure at the Lünen plant in 2025 by adding four steam storage units. This enables increased utilization of waste heat and an effective annual reduction of up to 4,900 tons of CO₂.

Furthermore, the tankhouse overhaul was completed in 2024. The existing tankhouse basins and the facility’s entire infrastructure were modernized and/or optimized over the course of five years. The entire project required a total of € 60 million and has significantly improved energy efficiency at the Lünen site with an increase in throughput and cathode quality in electrolytic copper refining at the same time.

Responsible operations to protect the environment in the vicinity of the site

Aurubis considers the protection of biodiversity one of the major environmental challenges of our time. Therefore, biodiversity has also been one of Aurubis' environmental targets for several years. Since the plant site in Lünen is located only a few kilometers from several Natura 2000 nature conservation areas, it is important for the site to maintain and promote good conditions in the plant environment for species protection and biodiversity. As a matter of principle, the potential impact on biodiversity and the possibilities for promoting biodiversity are examined for every construction initiative or project.

Certified management systems for environment, quality, energy, and safety

The environmental management system at the Lünen site, which has been certified pursuant to EMAS and ISO 14001 since 1997, ensures that production and environmental protection targets are met, and that development opportunities can be optimally exploited. Together with the quality management system certified pursuant to ISO 9001, the energy management system certified pursuant to ISO 50001 since 2013, and the occupational safety management system certified pursuant to ISO 45001 since 2021, they form an integrated management system (IMS). The external audits carried out as part of the certification of the management system include a review of environmental data, compliance with legal requirements, and the effectiveness of operational processes.

Detailed environmental information on the Lünen site can be found in the current Environmental Statement (German only, english version to follow).

Environmental Protection - facts & figures

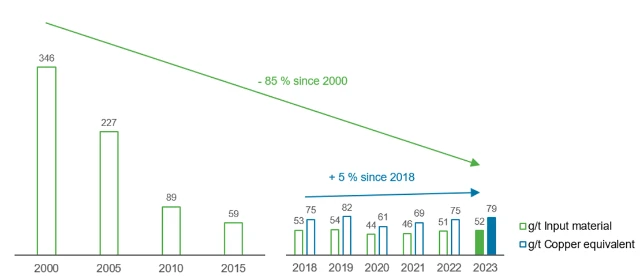

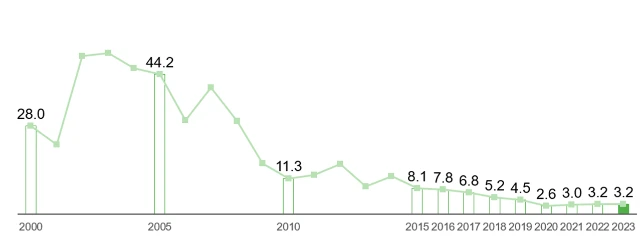

Dust emissions in g/t of input material and in g/t of copper equivalent

Dust emissions per ton of input material have been reduced by around 85 % since 2000.

Copper emissions per ton of copper output have been reduced by about 93 % since 2000.

With cathode copper production more or less unchanged, metal production is generated from a high and increasing input of complex and low-copper recycling raw materials. The average copper content in the raw materials is decreasing, and the content of accompanying metals such as zinc, tin, nickel, gold and silver is increasing significantly. The increasingly complex composition of raw materials is becoming more energy-intensive to process.

Energy awareness is now incorporated into the regular qualification/instruction of employees.

As part of the measures to enhance supply security at the Lünen site, an LPG system will be commissioned over the course of 2026. The air separation unit (ASU), completed in 2025 and scheduled for commissioning in early 2026, will provide an additional contribution to supply security. Moreover, in‑house oxygen production will eliminate a significant number of truck deliveries, further reducing the burden on the surrounding community.

Environmental Protection Measures & Projects

Degree of implementation/date/next steps:

- Assessment of the emission effects after closure of the smelting operations hall and, if necessary, closure of the KRS roof ventilation

Status: The project is in the basic engineering phase

Degree of implementation/date/next steps:

- New filter system installed in the sampling hall.

Status: completed. Filter was constructed and commissioned in summer 2023.

Degree of implementation/date/next steps:

- Separate treatment of the remediation water and improvement of the ratio of utilized to discharged surface water close to 100 %

Status: The previous targets have been achieved, and the water‑use concept aimed at preventing the discharge of unused process water has been developed. A schedule including preliminary investigations has been prepared. In 2025, pumping tests were conducted and treatment processes were tested.

Degree of implementation/date/next steps:

- Heat utilization and water quality of the anode smelter circuits and the leaching plant are being optimized to increase performance

Status: Concepts are under development with external support. Projects are included in the investment budget

Degree of implementation/date/next steps:

- Increase in direct heat utilization from waste heat

Construction of a steam storage system to optimize steam usage. The steam storage units minimize energy losses and ensure an optimized supply of process steam to boilers and production facilities.

Status: Completed. In operation since July 2025, annual savings: up to 4,900 t of CO₂ per year.

Degree of implementation/date/next steps:

- Efficiency increase KRS

Status: Annual savings of 36,400 MWh of oil and 10,000 t of CO2

Degree of implementation/date/next steps:

- Public disclosure

Status:The documents for informing the public are available online, and the visitor and contractor safety briefings have been revised. A general guideline on conduct and clothing requirements has been established for employees as well as external companies and visitors and is now part of the site induction training. In addition, a new brochure for public information has been published.

Degree of implementation/date/next steps

- Results improvement projects and project organization

Status:

- The system for the continuous improvement of procedures and processes (AOS) was merged organizationally with the Integrated Management System.

Milestones in Environmental Protection

As part of a new water concept, further improvements are planned with regard to sustainable water use. Further optimization of internal water use is planned for the coming years, including additional treatment of internal process water (reverse osmosis, evaporation). The goal is to use all water internally as far as possible and to completely avoid discharging process water into the public sewer system. Full realization of the project is scheduled for the end of 2026.

At the end of 2024, construction began on a new air separation unit. With an investment of around €40 million, this marked an important step toward strengthening the site’s supply security and reducing dependence on external deliveries. At the end of 2025, the plant was commissioned as planned and has since been producing oxygen and nitrogen entirely on‑site. The elimination of 8–9 truck deliveries per day has significantly reduced traffic and emissions in the region. At the same time, the use of nearly pure oxygen enables more efficient production and results in annual CO₂ savings of around 8,500 tons.

A new steam storage system was also successfully commissioned in 2025. With an investment of around €10 million, Aurubis took another important step toward increasing energy efficiency and reducing emissions. The system consists of four high‑pressure steam storage tanks and makes it possible to store surplus steam from copper production and feed it back into the process as needed. This eliminates the need for additional steam generation using natural gas, reducing consumption by around 2 million cubic meters per year and cutting CO₂ emissions by roughly 5,000 tons. With this project, Aurubis not only strengthens the site’s energy supply but also sends a clear signal for sustainable industrial innovation.

In June 2025, recertification with the Copper Mark seal was successfully completed.

The Aurubis sites in Hamburg and Lünen have successfully completed the certification process by the Copper Mark and now bear the recognized seal of quality for sustainability in the copper industry. Since March 30, 2020, mines and smelters have been able to verify their sustainability performance on a voluntary basis and have it verified by third parties. Currently, more than 40 sites have joined the Copper Mark. A pilot project is currently underway with companies in downstream copper processing. The certificate for the Hamburg plant already includes this processing step. The 32 sustainability criteria of the Risk Readiness Assessment from the Responsible Minerals Initiative (RMI) on topics such as compliance, child labor, environmental protection, and occupational safety apply to the Copper Mark. It is aligned with the Sustainable Development Goals (SDGs), the United Nations framework. For the criterion of responsible sourcing of copper, lead, nickel and zinc, the Copper Mark has also developed a due diligence standard that also serves to meet the standards of the London Metal Exchange (LME), one of the world's most important metal exchanges, for responsible sourcing of metals. In addition to the Copper Mark, the Lünen site also bears the Zinc Mark and Nickel Mark quality labels.

The modernization of the tankhouse started in 2019. Aurubis AG invested a total of € 60 million in the renewal of the plant over four years. The work included the demolition and new construction of the tankhouse basins, and the efficiency improvement of the plant has increased the capacity by about 10 %. During the modernization in sections, the plant remained in operation at 80 % capacity.

The tankhouse renewal project was initiated in April 2019. The first phase was completed in early 2020.

In 2022, the entire roof ridge turret of the tankhouse was renewed during the overall renovation.

Commissioning of a two-stage steam turbine (5.7 MWel) to use up to 300,000 t of process steam for internal energy generation and use.

Conversion of the plant's mixed sewer system into a separate sewer system (operational wastewater, sanitary water, and rainwater) in connection with rainwater retention and collection (RAN system, 9,000 m3 retention volume). This enables the use of collected rainwater as internal process water for cooling processes and thus a savings of more than 100,000 m3 of water drawn from the public supply.

Complete closure and suctioning of the smelter hall. As a result of this measure, the entire melting processes of the Lünen plant, from the bath melting furnace to the anode furnace, including the halls for transport and charging, have been completely suctioned off. Emissions from the site have thus been minimized far beyond the state of the art.

Commissioning of a converter furnace (TBRC) as part of the KRS+ efficiency project. As a result of this process technology improvement, the Lünen site was able to increase its throughput by more than 30 % while maintaining the same overall primary energy input for the plant.

Installation of a truck tire washing system, which all delivery vehicles must pass through before leaving the factory, to further minimize dust emissions from the factory.

Construction of a noise protection barrier at the material delivery in the southern area of the plant to reduce noise emissions from delivery traffic to the adjacent properties.

Implementation of the Kayser Recycling System (KRS) in the course of the plant modernization after the takeover by Aurubis AG (then Norddeutsche Affinerie AG). Commissioning of a highly efficient ISA bath melting furnace and a tin composite furnace with state-of-the-art filter technology to replace the site's old shaft furnaces.

Information to the public in accordance with the Major Accidents Ordinance

Download (PDF)

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

Acceptance catalog (German)

PDF

4 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

Copper Mark Award, Lünen

PDF

2 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

EMAS Registration Certificate

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

EMAS Validity Declaration

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

DIN EN ISO 14001 : 2015, Aurubis AG

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

DIN EN ISO 14001 : 2015, Aurubis AG, Annex

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

DIN EN ISO 14001 : 2015, Lünen

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

DIN EN ISO 45001 : 2018 Aurubis AG

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

DIN EN ISO 45001 : 2018, Aurubis AG, Annex

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

DIN EN ISO 45001 : 2018, Aurubis Lünen

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

DIN EN ISO 9001 : 2015, Aurubis AG

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

DIN EN ISO 9001 : 2015, Aurubis AG, Annex

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

DIN EN ISO 9001 : 2015, Aurubis Lünen

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

DIN EN ISO 50001 : 2018

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

Verification of Group-wide harmonized environmental data (German)

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

Specialist waste disposal company Material preparation plant (German)

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

Certificate initial treatment plant according to ElektroG (German)

PDF

2 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

Decision on the utilization procedure of Aurubis AG, Lünen, of the Arnsberg district government Decision on the utilization procedure of Aurubis AG, Lünen, of the Arnsberg district government

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

WEEELABEX Certification of Conformity

PDF

2 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

WEEELABEX/CENELEC Audit Summary

PDF

2 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

Zinc Mark Award, Lünen

PDF

1 MB

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

Nickel Mark Award, Lünen

PDF

1 MB

Dr. Aaron Weigelt

Head of Environmental Protection, Sustainability and Energy