Continuous cast shapes –

Aurubis SHAPES

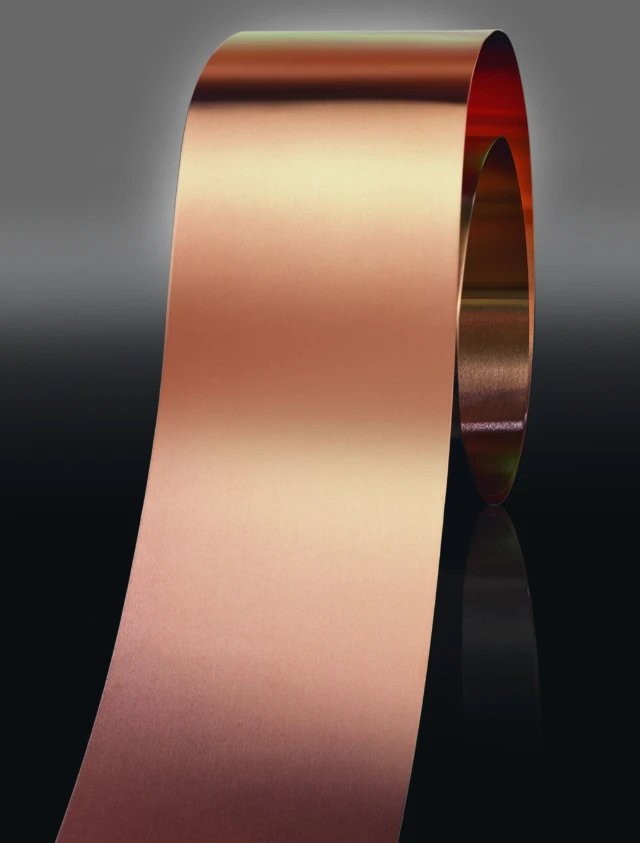

Aurubis SHAPES is a cast product characterized by a rich variety of shapes and copper materials. Our shapes are individually tailored to our customers' production processes and end applications. The product portfolio includes both oxygen-containing and oxygen-free copper materials ranging from high-purity to low-alloyed copper materials. Aurubis SHAPES therefore represent the optimal starting product for the fabrication of high-quality strip, foils, plates, pipes, profiles and forgings made of copper materials.

Basis for sophisticated applications

Aurubis SHAPES are ideal for sophisticated applications thanks to their consistently high quality. The range of materials extends from high-purity copper (purity of 99.99 %) to age-hardenable CuCrZr alloys and other high-performance alloys.

Aurubis SHAPES form the basis for a wide variety of products that require high electrical or thermal conductivity in combination with excellent strength and outstanding surface properties. They are thus not only a reliable basis for established applications but also a significant driver of state-of-the-art technologies.

Production capacity

per year

Copper content

different formats

It is particularly important to us to meet customers’ individual requirements and specifications so that we can ensure optimal processing and functionality in the following applications:

- Cable strip with the highest standards for welding suitability and surface quality

- Molds for foundry technology

- Lead frames

- Plumbing pipes and industrial tubes for air conditioning technology

Furthermore, Aurubis offers several processed products and special shapes such as anode molds, which are directly produced from our Aurubis SHAPES.

Electromobility

- Aurubis SHAPES are used in forward-looking e-mobility

- In power electronics, inverters require materials that offer high electrical conductivity along with tight dimensional tolerances

- This allows a great deal of energy to be transmitted in large cross-sections

Applications in demanding environments

- Aurubis SHAPES can be used to produce high-strength connectors that provide the requisite level of conductivity.

- These include copper-iron alloys, which meet stringent requirements for strength and conductivity in connectors that are decreasing in size

- Aurubis SHAPES made of CuCrZr alloys combine high strength and good electrical/thermal conductivity

- CuCrZr alloys form the basis for sophisticated products such as those found in rocket propulsion technology

Product portfolio

- Cu-ETP1 (CR003A, C11040)

- Cu-ETP (CR004A, C11000)

- CuAg0,04 (CR011A, C11400)

- CuAg0,1 (CR013A, C11600)

- Cu-OFE (CR009A, C10100)

- Cu-OF (CR008A)

- CuAg0,04(OF) (CR017A, C10400)

- CuAg0,1(OF) (CR019A)

- Cu-PHC (CR020A)

- Cu-HCP (CR021A)

- CuAg0,04(P) (CR014A)

- CuAg0,1(P) (CR016A)

- Cu-DLP (CR023A, C12000)

- Cu-DHP (CR024A, C12200)

- Cu-DXP (CR025A)

- CuCr1 (CW105C, C18200)

- CuCr1Zr (CW106C, C18150)

- CuSn0,15 (CW117C, C14410)

- CuZr (CW120C, C15000)

- CuFe0,1P

Formats and dimensions

- Diameters: 150 mm - 500 mm

- Lengths: 490 mm - 8,900 mm

The SHAPES product brochure lists the dimensions of all available formats.

- Widths: 405 mm - 1,280 mm

- Thicknesses: 160 mm - 320 mm

The SHAPES product brochure lists the dimensions of all available formats.

Sustainability

CO₂ footprint

in kg CO₂ equivalents per t of shapes

Already small and still shrinking: The environmental footprint of our products Copper, tin, silver, gold and other metals are the elements at the heart of digitalization. So for sustainable development, it is crucial that we find environmentally friendly ways of producing these essential metals. With our life cycle assessments (LCAs), we have again demonstrated that we are pioneers in sustainability.

1.574 kg

Aurubis SHAPES

Our biggest impact? Less Impact.

Sustainability excellence: Our certificates and awards

Aurubis is setting new standards for sustainability in the metals and mining industry – third-party verified and internationally recognized.

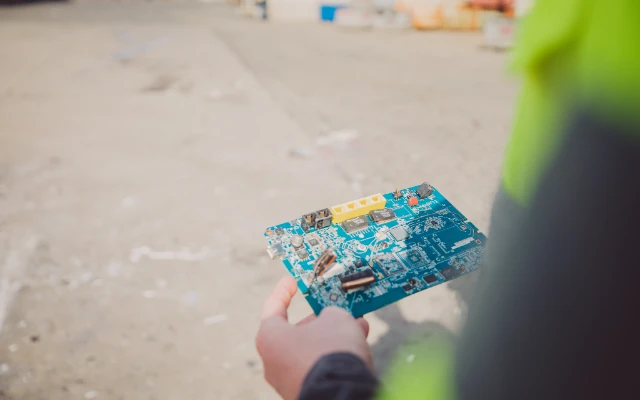

Recycling and production processes

Automating billet handling

The final steps in the continuous cast copper shapes process have now been almost fully automated with the assistance of a state-of-the-art heavy payload robot. The continuous casting plant at Aurubis in Hamburg is setting new standards in automation technology. The innovative robot is specially designed for extremely heavy payloads of up to 1,000 kg and handles the complex processes at the end of the continuous cast copper line with ease. It can process 80 % of all billets produced in the casting plant completely automatically, considerably increasing efficiency.

Um das video zu sehen den QR code scannen

Aurubis – a customer-oriented partner

Aurubis produces a wide range of metals and semi-finished products and makes an important contribution to the circular economy through multimetal recycling. Supply security is ensured through fully integrated production from anodes to cathodes to copper products. This is also reflected by redundancies with four ROD plants and four tankhouses.

The metal extraction processes at Aurubis are continuously improved so they remain state-of-the-art. We draw on the unique expertise of our specialists in the extraction, processing and recycling of metals and complex compounds.

Aurubis is a solidly positioned MDAX company and is thus a strong, financially sound copper supplier for the long term. We offer customer-specific price hedging solutions with full pricing transparency.

Aurubis offers customers an option called copper on account (Wandelkupfer), which enables them to secure supplies for their own supply chain using copper positions. Customers can flexibly procure copper from Aurubis and provide it to their own suppliers through copper accounts.

For Aurubis, responsible corporate governance is an integral contribution to securing the company's future. The 2030 sustainability targets establish the framework for this purpose. They are a component of the Aurubis corporate strategy and are divided into the focus areas People, Environment, and Economy.

Downloads

-

Um die heruntergeladene Komponente zu sehen den QR code scannen

Product Brochure AURUBIS SHAPES

PDF

1 MB

Thomas Peter Samson

Head of Sales

Sales Copper Products

Co-Lead Tomorrow Metals

Thomas Frank

Technical Marketing Aurubis SHAPES

| Phone | +49 40 7883-2821 |